The Indispensable Roles of Inductors, Coils, and Chokes in Modern Electronics

In the realm of modern electronics, three essential components play crucial roles in ensuring the smooth operation of various devices and systems: inductors, coils, and chokes. These unassuming yet highly significant elements are the unsung heroes of the electronics industry, powering everything from our daily gadgets to complex industrial machinery.

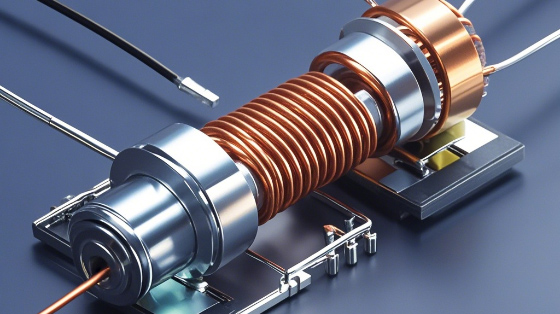

Inductors, at their core, are passive electrical components that store energy in a magnetic field. When an electric current passes through an inductor, it creates a magnetic field around it. This magnetic field resists changes in the current, resulting in inductive reactance. Inductors come in various shapes and sizes, from small surface-mount devices to large power inductors used in high-power applications.

One of the key applications of inductors is in filtering circuits. In power supplies, for example, inductors are used to filter out unwanted high-frequency noise, providing a clean and stable DC voltage to the connected devices. By blocking high-frequency signals and allowing only low-frequency or DC currents to pass, inductors help to improve the performance and reliability of electronic systems.

Coils, which are closely related to inductors, are typically wound conductors that can also exhibit inductive properties. Coils can be designed for specific purposes, such as radio frequency (RF) coils used in communication devices or induction coils used for wireless charging. RF coils are essential for transmitting and receiving radio signals, enabling wireless communication between devices. Induction coils, on the other hand, use electromagnetic induction to transfer power wirelessly, a technology that is rapidly gaining popularity in consumer electronics and electric vehicles.

Chokes, also known as inductive chokes or line filters, are a specific type of inductor designed to block high-frequency currents while allowing low-frequency or DC currents to pass. Chokes are commonly used in power supplies and electrical circuits to reduce electromagnetic interference (EMI) and improve power quality. By suppressing high-frequency noise and spikes, chokes help to protect sensitive electronic components from damage and ensure stable operation of the system.

In industrial applications, chokes are often used in motor drives and power converters to smooth out the current waveform and reduce harmonic distortion. This not only improves the efficiency and reliability of the motor or converter but also reduces electromagnetic emissions, which is important for meeting regulatory requirements and minimizing interference with other electronic devices.

The design and manufacture of inductors, coils, and chokes require precision engineering and advanced materials. High-quality magnetic cores, such as ferrite and powdered iron cores, are used to enhance the inductance and magnetic properties of these components. The winding techniques and materials used also play a crucial role in determining the performance and characteristics of inductors and coils. For example, copper wire is commonly used for its high conductivity and low resistance, while enameled wire provides insulation and protection against short circuits.

As technology continues to advance, the demand for more efficient and compact inductors, coils, and chokes is on the rise. Miniaturization is a key trend in the electronics industry, and manufacturers are constantly striving to develop smaller and more powerful components without sacrificing performance. This has led to the development of new materials and manufacturing processes, such as multilayer ceramic inductors and printed circuit board (PCB) coils, which offer higher inductance values and better performance in a smaller package.