Chip manufacturing consumes an astonishing amount of water

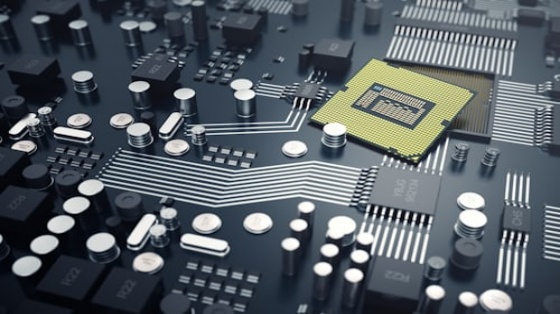

The rapid development of the semiconductor industry and artificial intelligence data centers may bring enormous pressure to global water resources. Producing advanced chips and cooling systems requires a large amount of ultrapure water. Although factories consume millions of gallons of water every day, equivalent to a city with a population of 60000, the technology industry is improving water recycling and reuse processes.

With the rise of artificial intelligence, water resource pressure has become more significant. Artificial intelligence data centers can use up to 19 million gallons of water per day, equivalent to the demand of a city with a population of 50000. Climate change has exacerbated this issue, and it is expected that by 2030, nearly half of new facilities will be located in areas with extremely high water risks. These factors not only threaten the local environment, but also threaten the global semiconductor supply chain.

Semiconductor manufacturing requires a complex six step process and consumes a large amount of ultrapure water. For every 1000 gallons of ultrapure water produced, 1400 to 1600 gallons of municipal water are required. A large semiconductor factory that produces 40000 wafers per month consumes 4.8 million gallons of water per day, equivalent to the annual water consumption of 60000 residents. TSMC, the world's largest chip manufacturer, is building a new factory in Phoenix, Arizona, promising to reuse 65% of its water. This indicates that people are paying more and more attention to water conservation, and also demonstrates the enormous scale of this problem: the water consumption of semiconductor factories is comparable to that of Hong Kong, which has a population of 7.5 million.

The technologies we rely on - from smartphones and computers to LED light bulbs and cars - cannot function without semiconductors. And the survival of semiconductors cannot do without water - a large amount of water.

The increasing demand for chips in the technology industry has brought greater pressure to the already overwhelmed water system.

Semiconductor factories rely on water to cool their systems and generate electricity - according to a global report by Standard&Poor's, their water consumption is equivalent to that of Hong Kong, which has a population of 7.5 million.

But what really drives the industry's demand for water is its demand for ultrapure water, used to flush residues on silicon chips during the manufacturing process.

Ultra pure water is thousands of times cleaner than drinking water, and is treated through processes such as deionization and reverse osmosis to remove pollutants, minerals, and other impurities that may damage the chip. Approximately 1400 to 1600 gallons of municipal water are needed to produce 1000 gallons of ultrapure water.

Nowadays, an ordinary chip manufacturing factory can use 10 million gallons of ultrapure water per day - equivalent to the daily water consumption of 33000 American households.

As the world's largest chip foundry, TSMC's operations may be disrupted due to water resource issues, affecting the entire global semiconductor supply chain and increasing prices for buyers.

In addition to the extensive use of water, chip manufacturing also generates wastewater containing pollutants (including heavy metals) that are toxic to aquatic ecosystems and humans.

Some manufacturers have promised to offset the impact of increased water usage. For example, a new chip factory built by TSMC in Phoenix, Arizona, has announced that it will recycle approximately 65% of its water usage, reducing its reliance on urban water supply. Due to the historical water scarcity of the Colorado River, the region is struggling to cope with population growth and increasingly severe water scarcity issues.

At the same time, Intel, which is building two new chip factories in Chandler, a suburb of Phoenix, has partnered with the city to establish a recycled water facility. Reclaimed water will supplement groundwater supply and provide more water for Intel's cooling system.

But the problem won't disappear soon. The demand for semiconductors continues to grow, but chip manufacturing hotspots (including the western United States and China) continue to experience drought and extreme weather. In a survey of 100 senior decision-makers in semiconductor companies in 2023, 73% of people believe that natural resources, including water, are one of the environmental factors that pose the greatest risk to their business.

Enterprises may also face regulatory risks. For example, the water system around semiconductor manufacturing plants in South Korea and other places is severely polluted, leading to environmental violations.

The water resource risk in the semiconductor supply chain is one of the many issues that has prompted investors to collaborate with large technology companies on water resource sustainability through initiatives such as the "Water Resource Assessment Financing Program". Investors participating in the program encourage and support the companies that the program focuses on, striving to address the widespread impact they have on the water resources on which their value chain depends.

It is necessary to fully recognize the water risk factors in the supply chain, especially in the fields of chip manufacturing and metal mining, as shown in the results of a recent benchmark report that evaluated the water management practices of 72 companies on the initiative list.

One of the surveyed technology companies, Sony, discussed in a public disclosure the impact of semiconductor production on water resources and stated that it is working to reduce its semiconductor manufacturing plants' dependence on freshwater.

For example, the Nagasaki Technology Center, a production center under Sony Semiconductor Manufacturing, recycles approximately 80% of manufacturing wastewater. The company also plans to build a wastewater recycling facility outside the factory.

According to the company, water recycling and emission reduction activities help to maintain almost the same level of wastewater discharge from chip production as production increases. However, there is a need to increase transparency to understand whether the company is reducing the water risk of its own manufacturing and purchased semiconductors.

In addition to reusing and recycling water resources, semiconductor manufacturers can also identify lost water resources by upgrading their water monitoring systems and adopting new technologies that consume less water to improve water efficiency. It is important for companies to consider water risks in their business planning, such as facility site selection decisions.

Technology companies that purchase chips can drive these strategies through procurement policies, ensuring that they purchase chips from manufacturers that adopt the best water management practices. Large technology companies that manufacture their own chips should disclose relevant water risks and the plans or practices they have developed to mitigate these risks.

Related Information

- 2025.05.12 Intel terminates Deep Link program